Restore a balance wheel? What in the world does that even mean? Well, I just completed a tutorial on restoring a Singer potted motor. As I got to the end, it dawned on me that the process naturally incuded removing and reinstalling the balance wheel. Well, the balance wheel on these two machines is not the same solid balance wheel found on other Singer machines of the same vintage. The difference is the potted motor… A belt driven sewing machine has a solid balance wheel, while a machine with a potted motor has a “textolite” gear attached to the balance wheel that is driven by a worm gear on the motor.

This is where my attention to restoring the balance wheel on these machines comes from. These balance wheels have a shock absorbing mechanism built into the balance wheel hidden from view by the “textolite” gear. You can see how this works by holding the balance wheel in one hand and turning the gear in the other. The gear will move in relation to the balance wheel by about a quarter of an inch before it engages… in either direction. Singer included this feature to absorb the shock of the gear drive in starting or stopping the sewing mechanism.

I don’t know that many people know this mechanism exists, or that the machine can be improved by addressing it. I do know that I have come across many, and none have had any indication of being previously serviced. after 60 to 80 years of service, it just makes sense that the grease lubricating this mechanism has outlived its purpose, my experience with disassembling and servicing these balance wheels supports this. The same general process will work on other gear driven machines including the 301, 401A/403A, and 500A/503A.

It’s really easy… takes 15 minutes… the balance wheel is easily removed… it makes a noticible difference in how the machine feels… and I want to presuade you check this off of your maintenance list for your machine that once done, should last for years.

This is a short tutorial so I will begin…

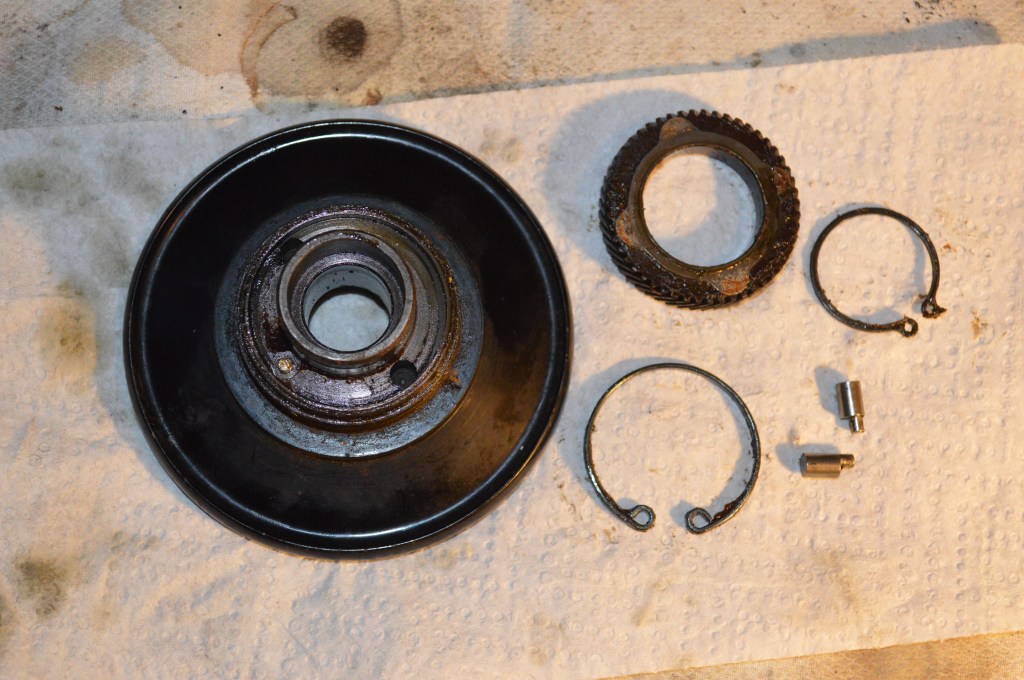

There are two configurations of these balance wheels. One has a collar with three screws retaining the gear, the other uses a “horse shoe” spring clip retainer. Here is a picture showing both. The pictures I used in this tutorial are a combination of both. The parts and process from the textolite gear down are the same.

Screw collar

Horse shoe clip retainer

The only difference in disassembly is this… One begins with loosening the screws and removing the collar. The other begins with removing the horse shoe clip. The horse shoe clip is a bit more challenging, but it simply involves prying the clip wider and away from the groove it sits in. There are two holes on the end of the clip for this purpose. There is a tool that is specially made for this, (like in the picture) but I have found that a pair of needle nose pliers works just as well.

Remove the collar or clip.

Remove the “textolite” gear.

Remove the thin metal cover.

What you see underneath is a spring with one end engaged with a stud in the balance wheel. Inside of the spring are two eccentric studs that pivot in their holes… remove the spring and eccentric studs.

Clean all of these parts.

Apply grease (I used Singer grease lubricant, any sewing machine grease will do) to the back of the textolite gear, eccentric studs, spring, and the area in the balance wheel these reside. Reinstall the eccentric studs and spring. Remember one end of the spring goes on the fixed stud in the balance wheel.

Replace the metal cover, the textolite gear, and the horse shoe clip or screw collar.

Apply grease to the gear teeth and the worm gear and reinstall the balance wheel.

That’s it!

You will notice the difference immediately and the mechanism will function as it is did when new!

I hope that this tutorial has helped you and answered a few questions in the process. Don’t hesitate to contact me if you have any questions, and please visit our Etsy store at https://www.etsy.com/shop/pungoliving, to see our restored fine high quality sewing machines.

As always, our tutorials are provided as a free resource to help you learn and maintain your vintage sewing machine. As our site has grown, so has the cost to keep and maintain it. Despite these cost, I will strive to continue posting tutorials and other relevant content for the benefit of the sewing community. If you found the content of this tutorial useful, please consider making a small donation to help me grow the site and help defray my costs… every little bit helps.

Help Support our Site…

Make a one-time donation

Make a monthly donation

Make a yearly donation

Choose an amount

Or enter a custom amount

Your contribution is appreciated.

Your contribution is appreciated.

Your contribution is appreciated.

DonateDonate monthlyDonate yearlyThanks for reading!

Lee

Great tutorial! This is the only tutorial I found how to restore the balance wheel AND remove all the parts. Thank you.

I am curious to know what you used to clean the textolite gear? Did you use a cleaner on it? I can’t find any good information on what cleaning product is safe to use to clean this gear. Thanks, John.

LikeLike

Hello John,

Thanks for your comment. I don’t really clean the textolite gear with anything more than wiping it down with a shop rag and making sure the gear teeth are cleaned. I use compressed air for this, but a toothbrush would work well.

The textolite gear is very durable and it has proved to be impervious to wear… cleaning the bits and pieces behind the textolite gear is where you will notice the most improvement.

I’m glad you found my tutorial useful, and have a great evening!

Lee

LikeLike

Hi Lee!

I just found and bought a lovely 301A from a dear lady who was cleaning out her house. She also had two modern Bernina’s that she sold to a friend of mine for an unbelievably low price. She asked very little for the 301 as well so I grabbed it. Her family told us that she took exceptional care of all her machines and were they every correct! Despite a bit of slightly greasy dust on the outside, this little 301 is immaculate on the inside!! The balance wheel turns at the touch of a finger and the motor purrs. It’s a beauty and I can’t wait to use it. I’ve been cleaning the outside VERY carefully with nothing but sewing machine oil and soft rags so she’s beginning to shine like a new penny. I haven’t tested the stitching yet but I’ll just bet it’s perfect. She’s a lovely old 1950’s era lady. Think I’ll name her Susanna after my beloved grandmother.

If you have any little insights on 301’s, I’d be most grateful if you’d share them. Many thanks!

P.S. Great tutorial on cleaning the Kenmore motors. They are so durable, dependable and easy to maintain. Their exceptional engineering shows.

LikeLike

Hello Suzanne,

I think you will be impressed with your new 301. They are certainly well know for their stitch quality. Like all Singers of the day they are made with close tolerances and tend to need very little adjustment and they are not generally abused like some full size machines. I expect yours is just fine. It does need regular oil maintenance, but you already know that!

The one area I would suggest you inspect closely is the bobbin case area. I have seen more than one 301 and 221 with thread wrapped around the back of the bobbin hook. It’s pretty easy to fix if it is though.

Google “Singer301.com” and you will find a lot of information about your machine.

I have done some 301 restorations and if you use the search function on my site you will find them. Perhaps looking at the machine through the restoration steps will help familiarize you with your machine and give you some pointers as well.

Keep me posted and let me know how it goes!

Lee

LikeLike

My “Susanna” continues to hum quietly and stitch beautifully. She’s a joy to use. I did check the bobbin case and found it to be clean. As mentioned above the former owner’s family insisted she’d had it “tuned up” regularly. They were telling the truth. She’s a gem.

Recently, I was thrilled to find an 81 years-young 201-2 in surprisingly good shape and for a fair price. Since my 301 was already named after my grandmother, I decided to name the 201 simply “Granny”. I took my time to clean her thoroughly. She had no rust but was a bit dirty in places. I disassembled all that I’m capable of and carefully put her back together after everything was shining. I had to buy a new power cable/foot pedal assembly, but her wiring from motor to outside connector was completely intact and the motor itself was amazingly clean, it just needed a little fresh grease in the wells. I took apart and cleaned the balance wheel, now it turns almost at the touch of a finger and so smoothly that it doesn’t make a sound. I managed to re-time her (with some helpful advice) and she sews a beautiful seam. To test her out, I worked on a project that other machines wouldn’t handle. It included a rubbery cabinet liner material on the bottom with two layers of cotton fabric on the top. A few of my more modern machines threw up all over the rubbery stuff, they buckled it or butchered it. “Granny”, on the other hand, went about her business with nary a hiccup, she didn’t mind the rubber stuff at all. She just purred along. These are Amazing Machines!!! My only problem now is which machine will I use next? The Kenny 158-1040? Susanna? Granny? My 1954 Kenny with the 1.5 amp motor and chain drive that powers through almost anything? One of my other Kennies? Agh! my head is spinning, but it’s a great problem to have.

The type of tips and advice you give are what gave me to confidence to work on Granny. You are absolutely wonderful; thank you so much!

LikeLike

Hello Suzanne,

I’m glad that you found a 201! They are amazing machines. You really do need to use one to understand why it has the reputation it has! Which machine you use is really a good question. in fact, you should use each one occasionally because they need to be used and the more they are used, the better they run. I guess my advice would be to exercise each one depending on the project and which machine proves the best. You certainly have choices and are fortunate to have the machines at the ready.

As always, please don’t hesitate to let me know if there is anything I can do to assist you. I do enjoy helping folks get their great vintage machines up and running. My goal is to keep as many old great quality machines in the stream as possible. Hopefully, other folks will turn to them and begin to use them as well. Thank you for your words of encouragement!

Have a wonderful day!

Lee

LikeLike

Hi, thanks for this tutorial. When replacing the textolite gear where does the little stud on it go? Facing down just anywhere or facing up?

LikeLike

Hello Anette,

The stud faces down and engages in the small loop on the spring (visible under the thin cover).

I hope this helps!

Lee

LikeLike