This is not the first 158.1430 I have restored. I’ve done a few. The 1430, and it’s kissing cousin the 158.1410, are in my opinion one of the best full size all purpose garment making sewing machine Kenmore produced in their long list of 158 series sewing machines. That’s why I am always on the lookout for the right 1430 to list in our Etsy shop Pungoliving. That’s not to say that other Kenmore’s are lacking in any respect, it’s just that these machines have just enough features to tackle just about any sewing project. It is not a cam compatible machine so it does not have 30+ stitch patterns to choose from. But the 11 built in stitches include enough stretch stitches to accommodate just about any sewing project (where you don’t need 30+ mostly decorative stitches) you can imagine… and they are tough.

Made in 1974 between 1975, with the exception of the plastic balance wheel ring, and other cosmetic features (panels and dials), this is an all metal sewing machine. This is particularly important as the internal cams, gears, linkages, and assemblies are metal, and this is what gives these machines such longevity.

Similar to many Kenmore 158 series machine, it has a 1.0 amp motor, a reduction belt drive to power the machine, drop feed dogs, hyper lift foot extension (lift), and a class 15 oscillating hook. For this machine, it is a center homing needle and a low shank presser foot.

The condition of this machine was very good to start with. the sewing assembly was free of old oil varnish so commonly found on these machines. The paint is in excellent condition with only a few small scratches and chips here and there. The Plastic balance wheel and stop motion knob has yellowed from age (So commonly found that I call it “Kenmore yellow”), but this can be corrected to return them to their original color. An excellent candidate for restoration, I am looking for a great outcome.

So, moving on to the restoration, here is the machine in it’s original condition.

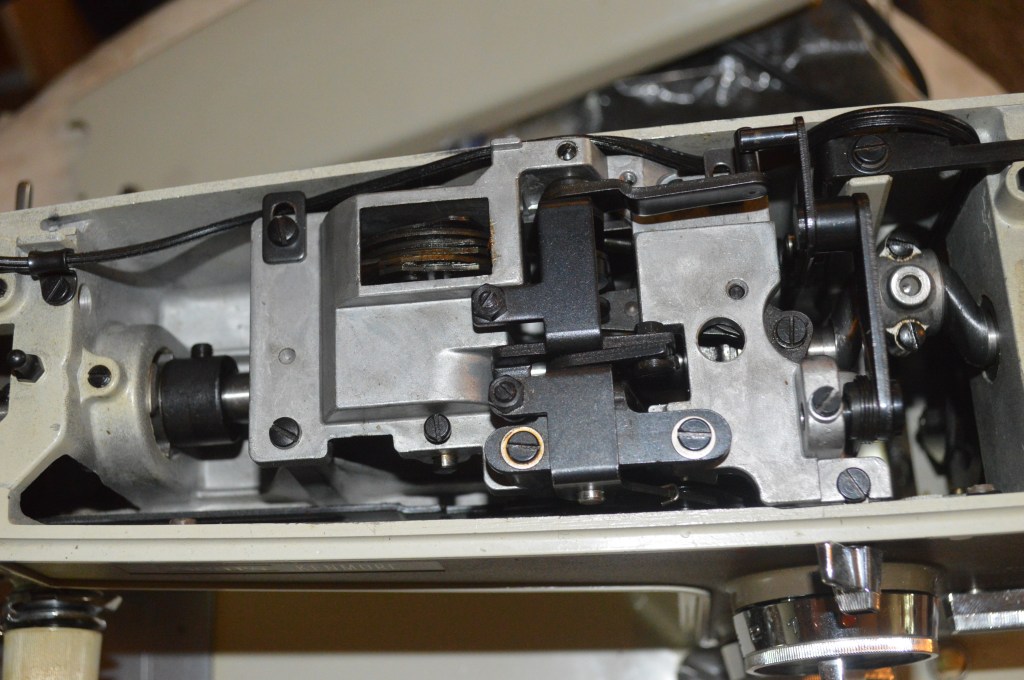

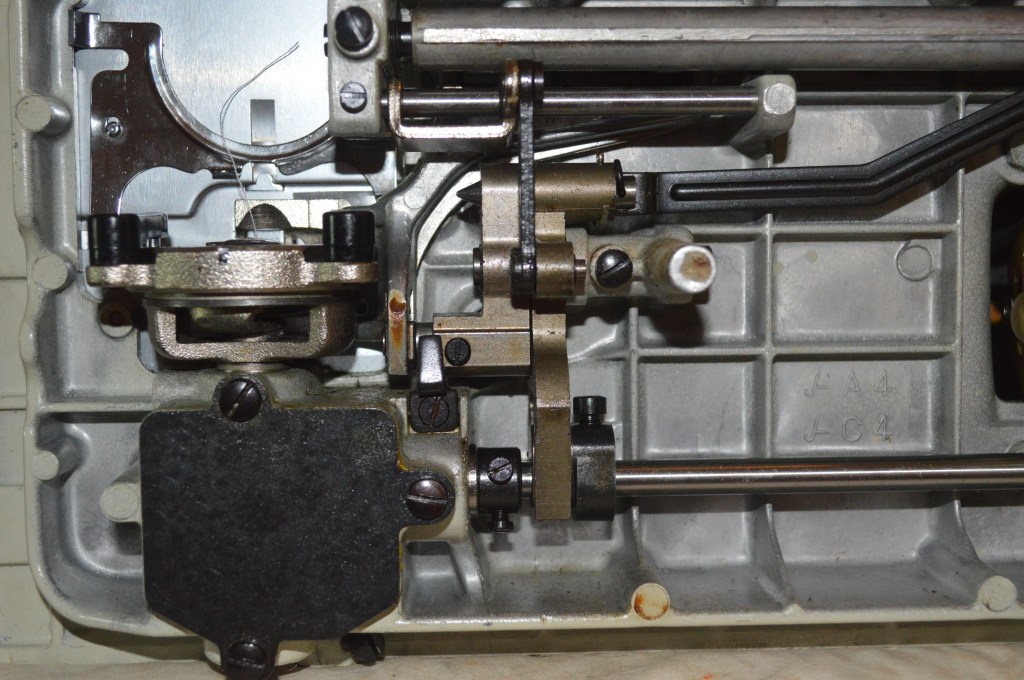

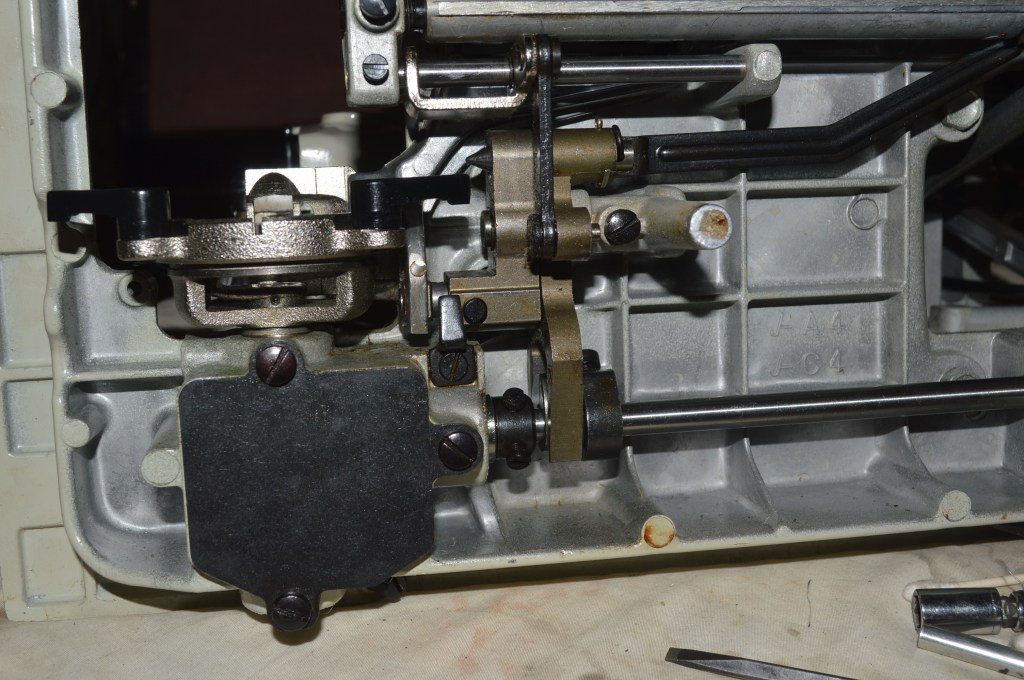

Looking at the mechanisms, all that is required is minimal disassembly and cleaning.

This is done with the goal of removing any old, dust, dirt, and lint. The cleaned mechanisms are re-lubricated with sewing machine oil.

Part of any restoration is to disassemble the motor and polish the commutator. This motor refurbishing restores the motor’s power and performance.

Commutator before polishing

Commutator after polishing

Motor reassembled and ready for installation

The next step is one I know needs to be performed without even looking first… it is the same on all Kenmore’s I’ve seen of this vintage, and I’ll bet it’s the same for any Kenmore you see. The grease in the oscillating gear case has hardened and needs to be replaced. Just as I suspected, here’s what you will find.

The old grease hardens and no longer lubricates the gears. All of this old grease is removed, the gears are cleaned, and the gear case is repacked with new grease.

The various parts such as the plate on the bobbin race cover and the bobbin case spring is removed for cleaning… these areas accumulate dirt and grime.

The yellowed parts are restored to their original color.

Before

After

Now the tension assembly is disassembled and cleaned.

Finally, the body of the sewing machine is deep cleaned. All of the assemblies are reassembled in the machine, oiled, and adjusted. The only little thing remaining is the scratches. They are very minor on this machine and hardly worth mentioning, but with all of the effort to ensure the machine runs like new, why not make it look like new? This is done my color matching the paint color and blending in the scratches with an air brush. The following pictures show these scratches side by side, before and after.

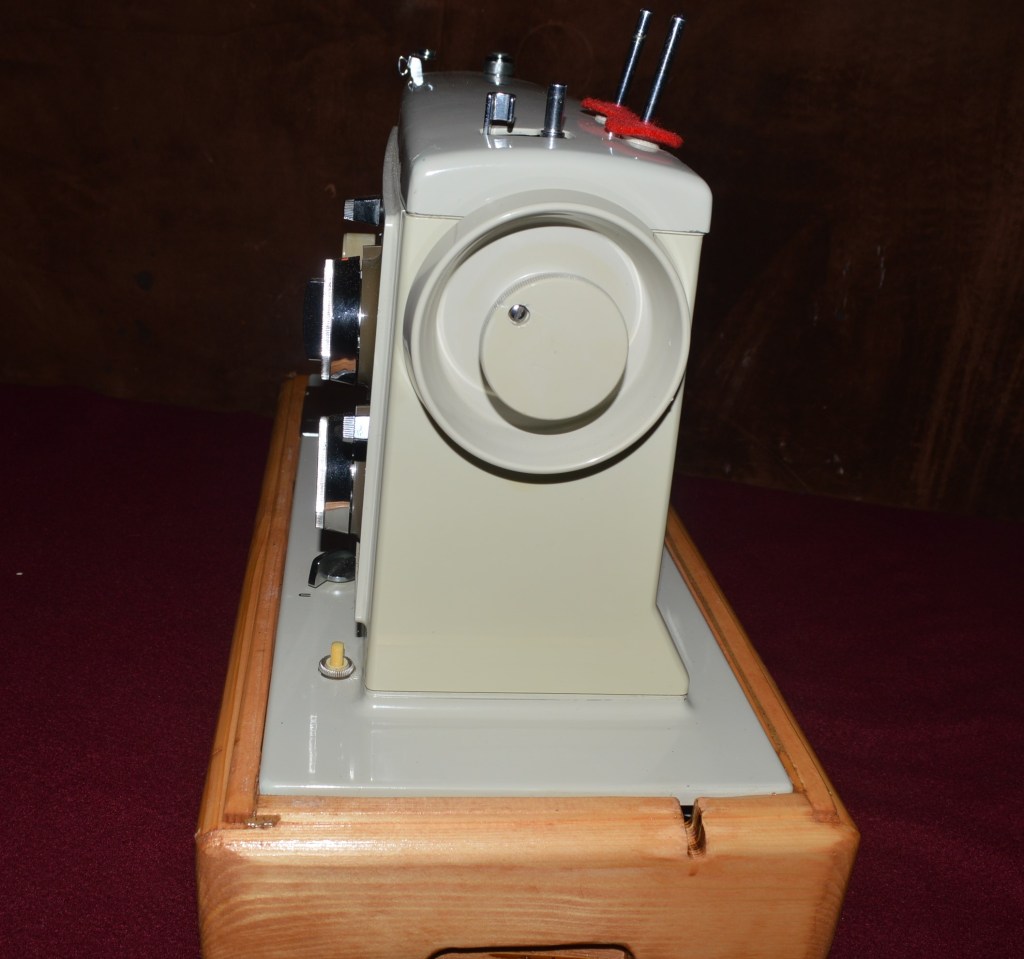

This machine came to me absent a case. For practical reasons, and because it will look great together, I built a custom pine base for the machine to sit in. Even though this machine will sew on a table without a base… a quality base compliments a quality machine.

Well, that’s about all that needed to be done to restore this 1430 to look and sew like new. The outcome for this machine is not surprising, it sews quietly for a Kenmore, has great piercing power, and all the stitches are excellent. It is an excellent example of a 158.1430 and with simple oiling and cleaning, it is ready and willing to sew reliably for years to come.

Here is the machine before restoration…

Here is the machine after restoration…

If you like what you see please visit our Etsy store at https://www.etsy.com/shop/pungoliving, and see this beautiful model Kenmore 158.14301 and all of our other restored fine quality vintage sewing machines. If you have any questions, please contact Lee at Pungoliving@gmail.com.

Thanks!

What a beautiful machine! If you don’t mind my asking, how do you get rid of the “Kenmore Yellow”? I thought that this type of yellowing on plastic was irreversible. I’ve obviously got that wrong.

LikeLike

Good morning Jeffery,

It’s really very simple… you need to get a bottle of hair color developer, I use a product called “Salon Care 40 volume creme developer”. It is essentially a very concentrated hydrogen peroxide, and 40 percent is the highest concentration you can buy without a license.

Coat the yellowed plastic in the creme developer (wearing gloves of course), place in a zip lock bag, place it in direct sunlight, and let it sit. The UV rays in the sunlight will reactivate the plastic component chemical that causes the yellowing, and it will return to it’s original color. Rinse the developer in clean water and let it dry… that’s it.

It may take 2 applications and 2 days of sunlight to get the maximum benefit, but it works great.

I confess I don’t understand the chemistry, and as such consider it magic.

Good luck and let me know how it works for you.

Have a great day!

Lee

LikeLike

What a great tip, thanks Lee! I’ve a number of plastic items around the house that used to be white and I’ve tried everything I could think of to clean them. One of my sewing machines is included in the list, a Singer with a plastic case. I’m looking forward to trying this out!

LikeLike

I am working on a Kenmore 1430 and the sriracha selector knob would not turn to the red dot, straight stitch. I oiled everywhere I could find something moving and ultimately loosened the screw of the arm that runs the stitch selector. I could then move the selector knob to straight stitch however, upon tightening, it would not go back to the red dot. Long story short, the selector now moves but the stitch the selector is set at is not the one the machine makes. How do I reset the cam follower to be on the correct stitch?

LikeLike

Hello Cynthia,

Let me take a look at my 1430 to reacquaint myself with the stitch selector dial and I’ll try to help you sort your problem out.

Have a great evening!

Lee

LikeLike

Hello Cynthia,

I looked at my 1430 and perhaps I can help you. If you like, please send me some pictures of the stitch modifier and the stitch length dial set to the red dot from the perspective of looking down inside the top cover, Send them to pungoliving@gmail.com and I’ll try to help you!

Lee

LikeLike

Thank you, I actually got is fixed! Happily. Thank you for your response.

LikeLike

What is the blue grease in the gear box. The yellow grease in mine was stiff and came out nearly in one piece! I replaced it with Triflow synthetic grease. Does it need to be globbed in there or is brushing the grease onto the gears enough?

LikeLike

Hello Cynthia,

The blue grease is a Mobil marine grade synthetic grease. Tri-flow grease is just fine. You should fill the box about 1/3 to 1/2 full. The idea is that the gears have ready contact with the grease at all times. I would bet that the old, hardened grease you removed had gear teeth impressions in it… no grease was getting on the gears.

Hope this helps!

Lee

LikeLike

My mom hadn’t used the machine in over 20 years and now it just barely moves. I was trying to lube all the metal components with silicone spray to see if it would at least move a little. Without tension, the motor spins freely but as soon as i tighten the wheel, the machine does not move the gears.

LikeLike

I am unable to remove the head from the base to clean underneath the mechine. How do I take out the top?

LikeLike

Hello Vasant,

I’m not sure I understand your question.

Can you take a picture of the location of the problem to pungoliving@gmail.com? I may be able to assist you further.

Have a great day!

Lee

LikeLike

Thank you very much for your response. I found a local repair service and resolved the problem.

Kind of you to reply,

Thanks again, Vasant

LikeLike

I hope your still up and running! What an informative site.

Thank you!

Lynn

LikeLike

Hello Lynn,

I’m still up and running and enjoying what I do!

Thanks for asking!

Lee

LikeLike

What are the differences between this and the 1410? Looking at a 1430 for sale locally. Did the 1410 have the 1.2 amp motor but the 1430 has a 1 amp?

LikeLike

The machines use the same motor. The most obvious difference is the 1430 has the stitch selections on the upper dial while the 1410 has the stitch selection dial on the bottom. As a consequence the inner workings are a bit different, but in function and operation they are basically the same machine. Either is good and the 1430 is a good choice.

I hope this helps!

Lee

LikeLike

I ended up picking up the 1430 and I cannot believe how smoooooooooth this thing sews. Smooth, quiet, and the stitching is as perfect as it could possibly be. Still hoping to get my 17300 back and running – will get back to you with pics on that one, I commented on another post. 🙂

LikeLike

Hello, I have a Kenmore 1430. I know that it will sew well but I am having trouble with tension and stitching. I am sure by reading your blog about refurbishing that mine will neep some TLC. My question is, do you clean machines if I were to ship it to you?

LikeLike

I’m interested in having my Kenmore 158.1401 serviced and the reverse mechanism repaired. I live in central valley of California, can I deliver my machine to you? Thank you for considering my request. Looking forward to hearing from you.

LikeLike

Hello Sue,

I live in Virginia Beach, Va. The shipping too and from would be pretty expensive.

LikeLike